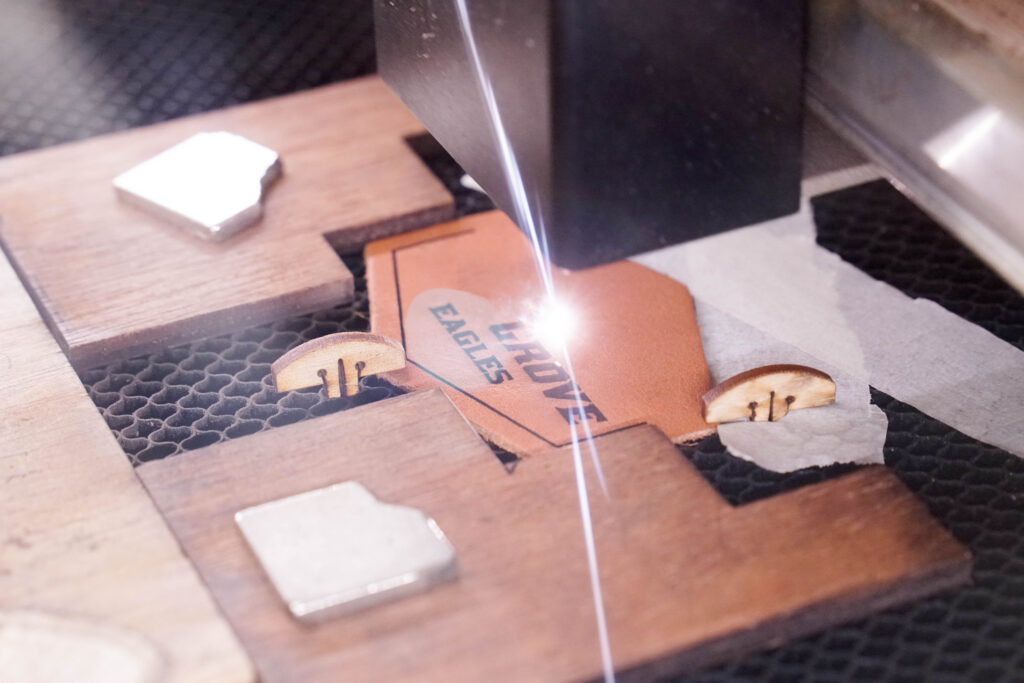

Here at SLC we’ve got a sharp team of 4 in our laser engraving department. Each team member brings something specific and unique to the department. We’ve got Holly, who does a lot of the graphic design work for the laser engraving department and the marketing department. She is a jack-of-all-trades when it comes to helping SLC out; from creating logos and stamps to creating new ads for Springfield Leather. Our next team member, Zach, runs our laser engraving machines, of which we have 5! He does a lot of customer relation work with folks that call in inquiring about work they need done or if they are interested in purchasing a Glowforge laser engraver. Our laser engravers carve out acrylic templates, both single templates and in bulk for products like bags, wallets, purses and more! Our laser engraving machines also engrave hat patches, weight-lifting belts, large-scale maps, and almost anything you can imagine from patterns, to intricate designs on select leathers and thin wood materials. There are endless options when it comes to laser engraving. We welcome you to give us a call to ask about something you need done or if you are interested in purchasing a laser engraver for yourself! (Watch an SLC live video featuring the Glowforge here) We also have one in our store, so come on by to see how one works in real time!

Next we’ve got Cole who runs our CNC machine, which stands for Computerized Numerical Control. Our CNC machine is a giant piece of equipment that has major possibilities. It’s main course of action is carving away excess pieces to leave pre-designed works of art. It can carve out signs, parts for retail displays that go in our store or shop, and even every day use items like decorative pieces that can be filled or covered in resin, which is a clear plastic mold that can have color added if you want to fill the shape of almost anything! The CNC machine is capable of cutting through even stone, granite and agate opening up many possibilities.

Last but certainly not least, we’ve got the laser engraving department’s outstanding leader, Matt! Matt has been working with SLC for quite some time and has really made the laser engraving department special. He goes out of his way to help customers and teach coworkers more about the laser engraving machines. Matt is very talented, and creates new and creative leather projects on his own during his spare time. He was even on an SLC live video where he showcased his geometric stamping skills (view video here). Matt communicates with customers who want custom stamps done and he stays very busy. Most folks that Matt works with are wanting a unique mark made so that they can stamp their projects with it. Around here we call this a “maker’s mark”, it is typically a customer’s personal business logo or unique “mark” they use to identify with their personal brand. Matt takes care of the process from thought to completed stamp to make sure that our customer’s are getting exactly what they envision. These stamps look great on completed projects and can be used for foil-stamping a mark as well. When I asked Matt what he loves most about working in the laser engraving department, this is what he said.

We are very thankful here at SLC for such a great department like the laser engraving team. They are a very important and innovative department that is making strides to go above and beyond for our customers and company!